- Home

- CAD/CAM Dental

- Dental Mills

- Amann Girrbach Ceramill Motion 3 Air

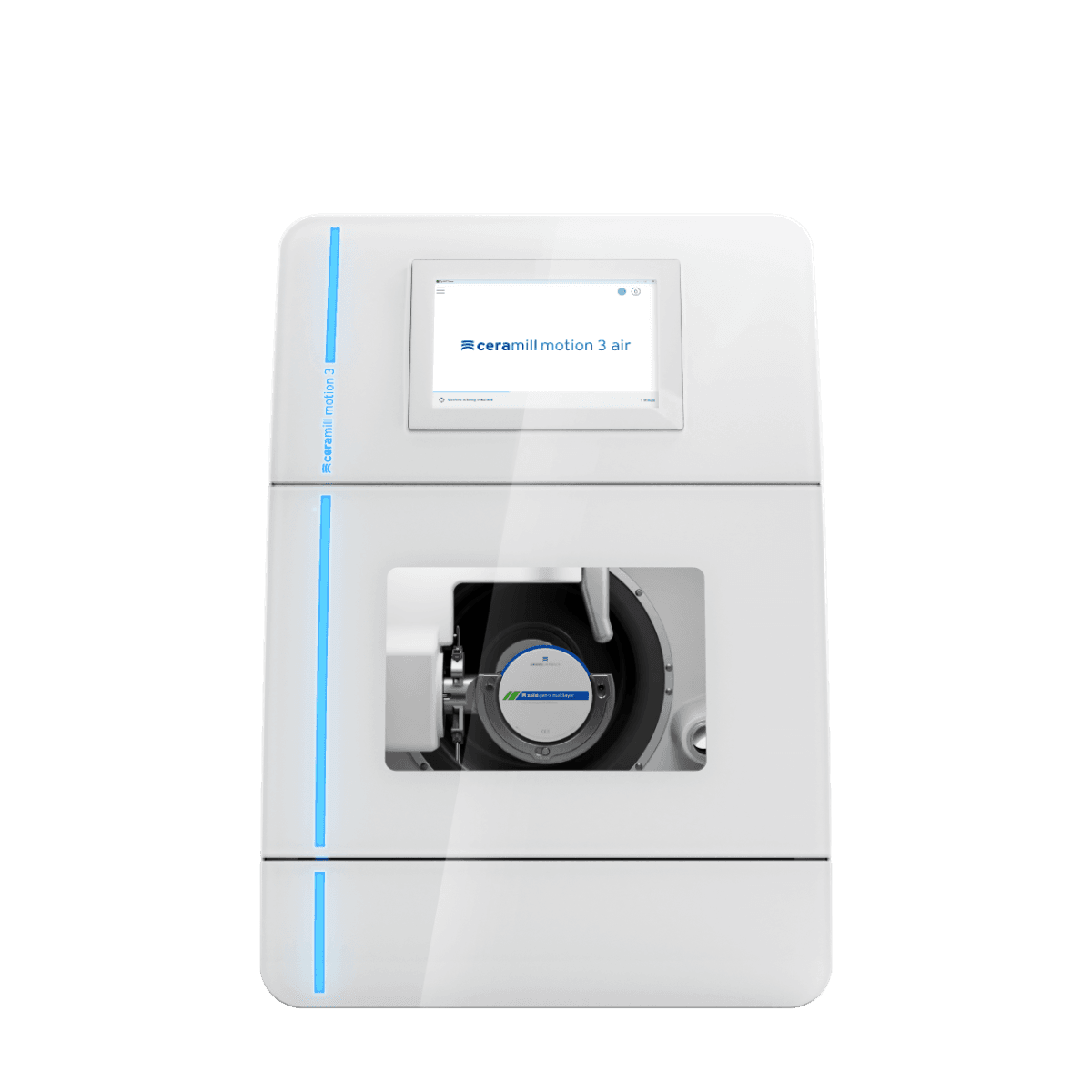

Amann Girrbach Ceramill Motion 3 Air

The Ceramill Motion 3 Air is the most intelligent digital 5x hybrid milling machine in the world that combines wet & dry processing in a single machine to enable an end-to-end digital workflow. From cleaning to maintenance, tool and holder management safeguarded against mix-ups, and semi-autonomous operation give you the freedom to devote yourself entirely to your profession instead of machine handling.

Description

The Amann Girrbach Ceramill Motion 3 Air combines convenience and excellence to supercharge your workflow. This is the most intelligent 5-axis hybrid milling machine that enables an end-to-end digital workflow while combining wet and dry processing in a single machine. Guided workflows make cleanup and maintenance a breeze and tool and holder management safeguard you and your team against mix-ups. An intuitive interface guides users safely through workflows and auto-calibration technology saves time. Automated tool management gives you real-time insights into your resources, boosting sustainability and maximizing value. Semi-autonomous operation allows you to use your time to focus on your profession, with no compromising and no rework.

- Integrated Air Supply. The motion 3 Air eliminates the need for external compressed air connections while maintaining high precision and reliability.

- Long service life. The Ceramill Motion 3 Air’s automatic reminder function for maintenance, care and service cycles provides reliability, in addition to guaranteeing a long service life.

- Precise, true to detail results. Thanks to advanced sculpting technology (C-Clamp), even the most delicate fissures on anterior tooth surfaces can be milled with exceptional precision. Innovative machining strategies, including rotational milling techniques like Carving Mode, Detailing, and Speedlining Mode, enhance the system's versatility.

- Intuitive and automated control. Self-service features, guided CAD/CAM production and maintenance, an intuitive HMI, an integrated camera, digital tool and holder management, and automatic calibration all streamline daily laboratory operations.

FAQs

Do you need an air compressor to run the Motion 3 Air?

No. The Motion 3 Air has a built-in compressor for easy installation.

What support is available for the Ceramill Motion 3 Air?

Remote service support is available from Amann Girrbach thanks to an integrated camera.

What kind of materials can the Ceramill Motion 3 Air process?

The Ceramill Motion 3 processes polymers, metals, ceramics, hybrids, and zirconia.

How does the Ceramill Motion 3 Air manage cutters?

The Ceramill Motion 3 features a RFID supported 6-fold tool changer, including management of replacement tools.

Specifications

- Built in compressor

- Processes Polymers, Metals, Ceramics, Hybrids, and Zirconia

- 6-fold tool changer including management of replacement tools

- 10” touch display for direct communication

- 5-axis control / 50I/min at 6 bar / 250w power consumption

- (DxWxH) 595 x 530 x 780 mm / 1.9 x 1.7 x 2.5 feet / 78 kg (172 lbs)

- High-performance super high frequency spindle (100,000 rmp)