How Digital Technologies Save Time, Leading to Greater Efficiency and Profitability

For me, the digital workflow in implant dentistry requires two primary systems—CBCT and an intraoral scanner. With those data sets, you have all the information you need to create custom, screw-retained temporaries and healing abutments, and the surgical guide. You can prosthetically plan the implant placement so you know exactly what you need and where it has to go. The true digital workflow means starting the diagnostic process with CBCT, then using digital intraoral scanning, 3D printing, and CAD/CAM milling—all the while moving the process along thanks to integrated software. We are also working with a lab that uses a digital workflow.

For me, the digital workflow in implant dentistry requires two primary systems—CBCT and an intraoral scanner. With those data sets, you have all the information you need to create custom, screw-retained temporaries and healing abutments, and the surgical guide. You can prosthetically plan the implant placement so you know exactly what you need and where it has to go. The true digital workflow means starting the diagnostic process with CBCT, then using digital intraoral scanning, 3D printing, and CAD/CAM milling—all the while moving the process along thanks to integrated software. We are also working with a lab that uses a digital workflow.

Recently, a patient came to my office with a fractured central incisor from a baseball injury he sustained many years ago. While still asymptomatic, he decided to seek treatment before it became an emergent situation. From an implant dentist’s perspective, this is one of the hardest cases to treat. However, with a digital workflow, treating the single anterior implant can be much more predictable.

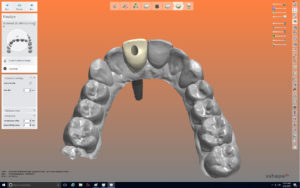

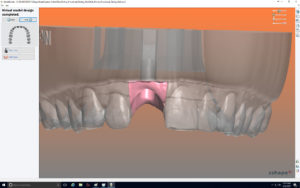

First, we used the X-MIND Trium from ACTEON to take a cone beam image of tooth No. 9. This provided us with amazing detail of the vertical root fracture. Next, an assistant took a scan of the tooth using the 3Shape TRIOS. I was then able to plan the ideal implant placement, and design a surgical guide and a patient-specific healing abutment using the 3Shape Implant Studio Software.

First, we used the X-MIND Trium from ACTEON to take a cone beam image of tooth No. 9. This provided us with amazing detail of the vertical root fracture. Next, an assistant took a scan of the tooth using the 3Shape TRIOS. I was then able to plan the ideal implant placement, and design a surgical guide and a patient-specific healing abutment using the 3Shape Implant Studio Software.

Compiling the data from these technologies, I was able to present the treatment plan and gain case acceptance at that same appointment. The data was then sent to Vulcan Custom Dental of Birmingham, AL, where they fabricated the surgical guide and custom healing abutment.

On the day of surgery, the tooth was removed atraumatically, keeping all the bone and tissue that was needed. The dental implant was placed, and the custom healing abutment and temporary crown were seated at the same time. The titanium CAD/CAM-milled custom healing abutment has BioHorizons’ exclusive Laser-Lok technology. It is shaped like the tooth being removed, which supports soft-tissue adherence and healing while maintaining the soft-tissue architecture. The goal in implant dentistry, obviously, is to have a total tooth replacement that is indistinguishable from the real tooth when the process is done, and the Laser-Lok technology makes that happen.

We let the site heal for about 3 months and then took another 3Shape TRIOS scan. ProSmiles Dental Studio of Rapid City, SD, used that image to create a custom screw-retained permanent crown that we seated a few weeks later. With the lab process, the end result is always going to need some personal touches—staining, glazing, and fitting it to the printed model. But at the end of the day, it is done with the highest possible accuracy and in the most efficient manner.

We let the site heal for about 3 months and then took another 3Shape TRIOS scan. ProSmiles Dental Studio of Rapid City, SD, used that image to create a custom screw-retained permanent crown that we seated a few weeks later. With the lab process, the end result is always going to need some personal touches—staining, glazing, and fitting it to the printed model. But at the end of the day, it is done with the highest possible accuracy and in the most efficient manner.

Because information is instantaneous in the digital format, many of these labs have the data and are sometimes starting to work on the project before the patient ever leaves the dental chair. That’s amazing! Many labs offer a discount for using the digital workflow, and the turnaround time is cut in half.

The ROI of Practice Efficiency

In addition to being more accurate than traditional dentistry, the digital workflow is quicker—both for the practice and in turnaround time for the patient. So many of these elements are delegated to team members, which saves clinicians time. In my office, staff are taking the CBCT scan and doing the intraoral scanning. The clinician can then use the accompanying software to quickly obtain a treatment plan, offer it to the patient, gain case acceptance, and then it’s “go” time for treatment at the next appointment. The case with the fractured central incisor was barely over an hour of pure doctor time for the whole project. Technology is only worth its expense if it makes you more efficient. Efficiency and profitability are all about the doctor’s time.

Today’s technology is seamless—the different systems all communicate with each other. My 5 practice locations are all powered by Dentrix and a web-enabled application for lab communication. When delivering a case, it obviously saves time to eliminate steps such as shipping and additional appointments. We’re seeing decreased lab remakes as a result of the higher accuracy of digital impressions, too. I feel that today’s technology has finally caught up after years of talk about being completely digital, quicker, and more efficient.

This article was originally published in Sidekick Magazine.

About the Author: Dr. Moody is an internationally known dentist, entrepreneur, instructor, and speaker in the fields of dentistry, practice management, technology, and implantology. He has practices in Nebraska and South Dakota, and is the founder of South Dakota Dental Implant Center, a leading Midwest dental CE provider. Dr. Moody knows the importance of dental continuing education as well as the need for mentorship and hands-on training. His conversational, real-life approach solidifies his educational philosophy.

About the Author: Dr. Moody is an internationally known dentist, entrepreneur, instructor, and speaker in the fields of dentistry, practice management, technology, and implantology. He has practices in Nebraska and South Dakota, and is the founder of South Dakota Dental Implant Center, a leading Midwest dental CE provider. Dr. Moody knows the importance of dental continuing education as well as the need for mentorship and hands-on training. His conversational, real-life approach solidifies his educational philosophy.