Request a Quote

Request a Quote

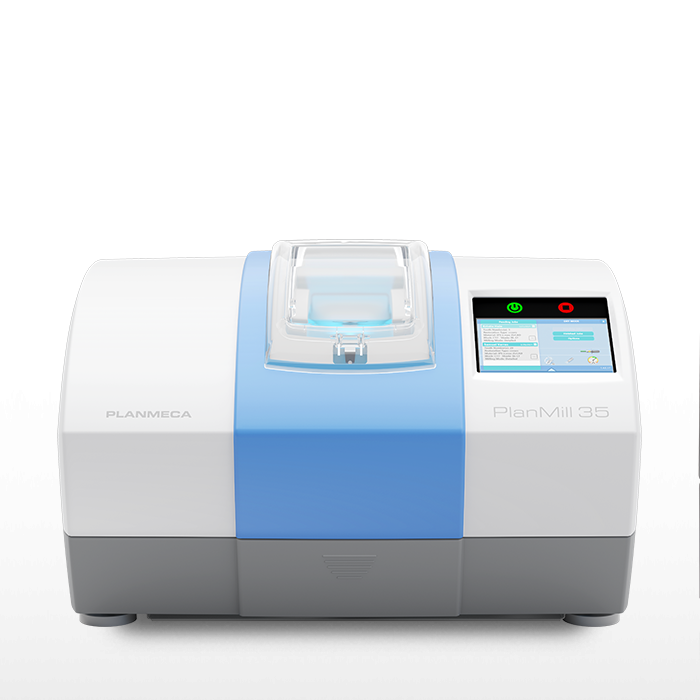

In-House Chairside Milling: Enhancing Dental Restorations with Ease and Precision

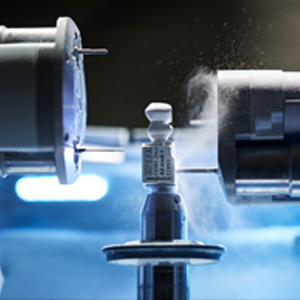

A dental milling machine takes patient care to the next level, allowing clinicians to mill veneers, crowns and bridges and other dental restorations with ease and precision. Not only can patients expect better-fitting, more esthetically-pleasing outcomes, but with CAD/CAM dentistry — specifically, chairside milling — practitioners can transform into complete solution providers, opening new revenue streams and expanding into more efficient, same-day dentistry workflows.

.

Whether you’re milling a simple dental crown or fabricating a more complex implant abutment, a state-of-the-art dental mill is designed to work seamlessly with digital impressions and the latest CAD/CAM software to deliver fast, accurate results. Browse our selection today — ranging from chairside milling units to complete CAD/CAM integrated solutions — from leading manufacturers such as Dentsply Sirona and Planmeca.

-

Highly esthetic results with CEREC® Primemill

CEREC Primemill, Dentsply Sirona’s new milling machine, has taken chairside dental restorations to the next level. Learn more.

-

The Basics of CAD/CAM Dental Milling

CAD/CAM technology has helped to transform the manner in which restorative treatment can be provided. In particular, the ability to provide patients with single-visit indirect restorations is appreciated by clinicians and patients. Chairside milling produces restorations that are at least as accurate as traditionally fabricated indirect restorations. Chairside milling also allows clinicians to optimize the process flow, reducing chairside time, increasing efficiency, and saving patients additional visits.

Loading, please wait ...

Loading, please wait ...